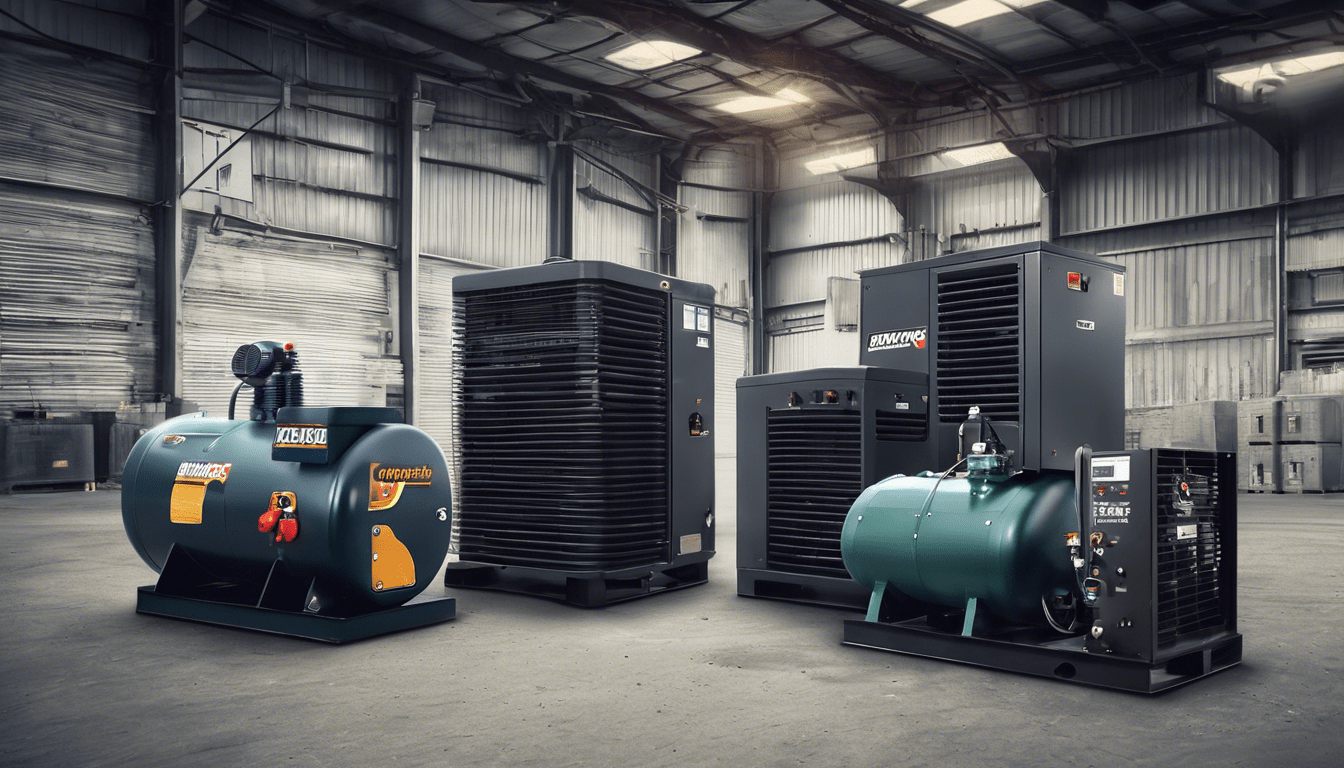

Selecting the right industrial air compressor in the UK hinges on understanding key features like energy efficiency, durability, and operational costs. Many models claim benefits, but evaluating real-world performance, brand support, and long-term value ensures smart investment. This guide offers a fresh perspective—beyond specifications, it highlights practical insights tailored to UK industries seeking reliable, efficient solutions that deliver both productivity and cost savings.

Key Factors in Choosing Industrial Air Compressors in the UK

Selecting the right industrial air compressor for the UK market requires attention to several critical technical specifications. Among these, the compressor’s pressure rating and airflow capacity are paramount: they must align precisely with the operational demands of your industrial processes. Choosing an air compressor that matches these requirements ensures optimal performance without overloading the unit or compromising output.

Additional reading : OnlyFans marketing: Promote your account and reach a wider audience

Energy efficiency is another vital consideration within UK industries, where reducing operating costs and minimizing environmental impact are key goals. Energy-efficient industrial air compressors consume less power during operation, translating into significant cost savings over time. This efficiency also aligns with increasing regulatory pressures and sustainability initiatives prevalent across the UK manufacturing sector.

Durability and maintenance frequency play crucial roles in long-term equipment reliability. Industrial air compressors designed with robust materials and straightforward maintenance protocols reduce downtime and lower total cost of ownership. For example, units featuring easily accessible filters and straightforward lubrication systems allow for smoother preventative maintenance schedules, a must-have for continuous industrial use.

Also to read : Enhance privacy and style with window films

By thoroughly evaluating the industrial air compressor features—pressure, airflow, energy use, and maintenance needs—buyers can make informed choices that cater to the stringent standards of the UK market. For businesses seeking further guidance on energy-efficient and durable systems, exploring specialized resources on Industrial Air Compressors can provide practical insights and tailored recommendations.

Top Industrial Air Compressors in the UK Market

When searching for the best industrial air compressors UK offers, efficiency and durability are paramount. High-quality Industrial Air Compressors deliver not only strong performance but also long-term energy savings. Among the options available, high-efficiency compressors stand out for reducing power consumption while maintaining output, which is essential for industries aiming to balance operational costs with sustainability goals.

High-efficiency compressors utilize advanced technologies such as variable speed drives and optimized motor designs. These features enable them to adjust power use based on demand, thus significantly lowering energy waste. For instance, industries with fluctuating air requirements benefit greatly, as the compressor adapts dynamically rather than running at full power continuously. This capability translates into tangible cost reductions over time.

Heavy-duty models address the rigorous demands of large-scale industrial operations. These compressors are designed for continuous, high-volume air supply with robust components that ensure reliability under harsh conditions. Their build quality often includes reinforced casings and enhanced cooling systems to withstand prolonged use in environments like manufacturing plants or construction sites. Companies requiring consistent and powerful air pressure prefer these systems due to their proven resilience and performance.

On the other hand, compact and portable options offer remarkable flexibility for smaller operations or tasks requiring mobility. These models combine sufficient power with ease of transport, enabling use across multiple sites or confined spaces. Despite their size, they maintain respectable efficiency levels, making them practical for workshops or mobile maintenance teams.

In a comparative context, selecting the ideal compressor depends on specific industrial needs, balancing capacity, price, and energy use. For those exploring comprehensive choices and detailed reviews, looking into Industrial Air Compressors reveals a spectrum of innovations catering to diverse situations—from bulk manufacturing to on-the-go servicing. Keeping these factors in mind will guide businesses to the most effective investment in the competitive UK market.

Detailed Product Specifications and Performance Ratings

When evaluating industrial air compressors, understanding their power ratings, pressure capacity, and airflow measurements is essential. Power ratings, typically expressed in horsepower (HP) or kilowatts (kW), indicate the energy the compressor can deliver. Higher power ratings generally translate to better performance but may also mean increased energy consumption.

Pressure capacity, measured in pounds per square inch (PSI) or bar, determines the maximum pressure the compressor can generate. This specification is crucial for matching compressors to specific industrial tasks, as some applications require higher pressures for optimal operation. Airflow measurements, expressed in cubic feet per minute (CFM) or liters per second (L/s), describe the volume of air the compressor can supply continuously. A higher airflow ensures that tools and processes dependent on compressed air run smoothly without interruptions.

Energy consumption and efficiency ratings are equally important when selecting industrial compressors, especially for UK businesses looking to minimize operational costs and environmental impact. Efficient compressors can operate at lower energy usage while maintaining required performance levels. Look for units with advanced motor designs and variable speed drives, which adjust power consumption based on demand, thus improving overall efficiency.

Longevity and warranty considerations also play a decisive role. Compressors designed with durable components and backed by comprehensive warranties provide peace of mind and reduce downtime risks. UK businesses should seek brands known for robust construction and reliable after-sales support, ensuring that their investment in industrial air compressors pays off long-term.

In summary, a thorough performance analysis that includes power ratings, pressure capacity, airflow measurements, energy consumption, and durability factors will guide you in selecting the industrial air compressors best suited to your needs. Industrial Air Compressors designed with these specifications in mind deliver optimal performance, efficiency, and operational reliability.

Cost Analysis and Value for Money in the UK Market

When considering industrial compressor cost in the UK market, understanding both the upfront purchase price and long-term operating costs is crucial. Many buyers focus initially on the price tag, but this only tells part of the story. The total cost of ownership includes energy consumption, maintenance, and potential downtime, all of which can significantly impact overall expenses.

The upfront investment for industrial air compressors varies widely depending on size, capacity, and technology. High-efficiency models may carry a higher initial cost but offer substantial savings over time. For example, energy-efficient compressors reduce electricity usage, which in the UK’s energy landscape can lead to appreciable financial benefits. These savings often offset the premium price, making such models cost-effective in the long run.

Financing options are also an important consideration, especially for businesses seeking to manage cash flow. Leasing and installment plans spread out the industrial compressor cost, enabling the acquisition of advanced equipment without large immediate capital outlays. Evaluating these options in the UK market can uncover solutions tailored to business budgets.

Moreover, the UK government and regional bodies sometimes provide fiscal incentives and rebates encouraging the adoption of energy-efficient compressors. These programs can lower the total cost of ownership further, making upgrades financially attractive.

Case studies often reveal compelling evidence: companies investing in energy-efficient industrial compressors enjoy reduced utility bills and maintenance costs. Over a few years, these savings commonly exceed the initial premium paid. This analysis highlights why evaluating both purchase price and operating expenses is essential for a complete picture of value for money in the UK industrial compressor landscape.

For an in-depth look at maximizing efficiency and cost benefits, exploring resources specialized in Industrial Air Compressors can be very helpful.

Brand Reputation and Customer Support for Industrial Compressors

When choosing from various compressor brand reviews, a strong UK presence and reliable customer support are crucial factors. Leading industrial air compressor manufacturers emphasize comprehensive UK customer support networks to ensure quick service response and minimize production downtime.

Customer satisfaction hinges heavily on after-sales service quality. Top brands offer robust warranty policies backed directly by UK suppliers, granting users peace of mind about repairs and maintenance. These warranties typically cover key components and encourage scheduled servicing, which enhances longevity and reliability.

In the UK market, brands that maintain dedicated support teams and prompt parts availability consistently receive higher marks in compressor brand reviews. This reliability, combined with widespread service centers, ensures that any technical issues or servicing demands are promptly addressed.

For businesses considering new equipment, evaluating the level of UK customer support alongside product specifications is essential. Not only does superior support reduce operational risks, but it also extends the compressor’s effective working life. Choosing a supplier that offers solid warranty coverage and responsive after-sales care is a practical way to maximize value from any industrial compressor investment.

For more insights on maximizing efficiency with well-supported compressors, consider exploring leading options among Industrial Air Compressors.

Buying Guides and Best Practices for UK Industrial Buyers

Choosing the right industrial air compressors in the UK market requires careful consideration of several factors tailored to your specific industry. Understanding industrial compressor buying tips can help streamline this complex process and ensure you invest in the most efficient and reliable equipment.

Key Features to Prioritize Based on Industry Type

The first question to address is: What features matter most according to your industrial sector? For manufacturing plants, high-pressure output and continuous duty cycles are critical to maintain productivity. Construction sites often need portable compressors with durability and rugged design, while food processing facilities prioritize oil-free compressors for hygiene compliance. Identifying your industry’s unique demands allows for a precise match to compressor characteristics, boosting operational efficiency.

Inspection Checklist Before Purchase

Before finalizing any purchase, an exhaustive inspection checklist is invaluable. Key checkpoints include verifying the compressor’s exact pressure rating, airflow capacity, and power consumption to ensure they meet your operational requirements. Check for warranty terms and the availability of local service providers to minimize downtime. Assessing the noise levels is also crucial, especially in urban or enclosed environments.

Maintenance Tips for Maximizing Compressor Lifespan

Maintaining an industrial compressor correctly significantly increases its longevity. Experts recommend adhering to a routine service schedule that includes checking and replacing filters, lubricating moving parts, and inspecting belts and hoses for wear. Many UK buyers overlook the impact of ambient conditions; ensuring compressors operate in clean, temperature-controlled environments can prevent premature failure.

Factors influencing long-term efficiency and reliability include the compressor’s build quality, frequency of use, and maintenance rigor. Evaluating suitability based on specific industrial needs involves balancing upfront costs against lifetime operating expenses. Early detection of common issues through regular troubleshooting can save significant repair costs later.

For a comprehensive understanding and more detailed options available for UK buyers, consulting detailed resources on Industrial Air Compressors is highly recommended. This approach ensures your purchase aligns with both immediate needs and future scalability.